201 Stainless Steel Coil

Classification :

PRODUCT DETAILS

Keywords: Jingye Steel Group Co., Ltd.

201 Stainless Steel Coil Description

Type 201 stainless steel is an austenitic chromium-nickel-manganese stainless steel, which is developed to save nickel. Type 201 is a low-cost alternative to traditional Cr-Ni stainless steels such as 301 and 304. The nickel is replaced by added manganese and nitrogen. It cannot be hardened by heat treatment, but can reach high tensile strength by cold working. Type 201 is essentially non-magnetic in the annealed condition and becomes magnetic upon cold working. In many applications, the 201 type may replace the 301 type.

Product Parameters

|

Product Name |

201 Stainless Steel Coil |

|

Type |

Steel Coil |

|

Thickness |

2.5mm-10.0mm |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

|

Width |

610mm-2000mm |

|

Standard |

ASTM, AISI, JIS, GB, DIN, EN, etc. |

|

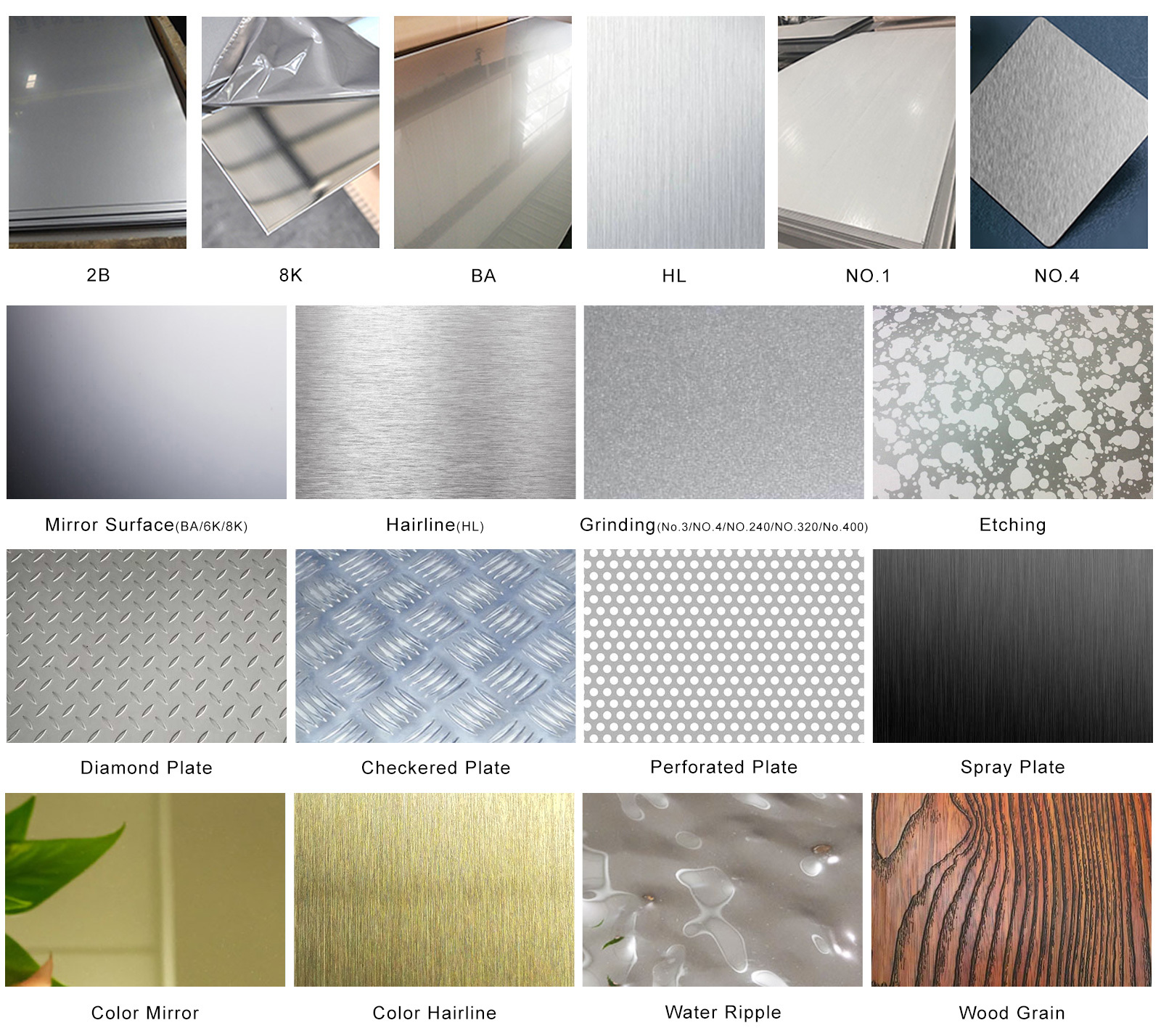

Surface |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Scope of Application |

Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

|

Certificate |

ISO, SGS, BV, etc. |

|

Production Technology |

Hot Rolling, Cold Rolling |

|

Edge Processing |

Edging, Trimming |

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.15 |

≤ 0.75 |

5.50~7.50 |

16.00~18.00 |

3.50~5.50 |

≤ 0.03 |

≤ 0.06 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥ 520 |

≥ 275 |

≥55-60 |

≤183HB;≤ 100 HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(μohm.in) |

|

7.8 |

197 |

15.7 |

16.2 |

27 |

Surface Selection

|

No |

China | Japan | USA | South Korea | Germany | India | Australia | Taiwan, China | |

|

|

GB |

JIS |

ASTM |

UNS |

KS |

DIN |

BIS |

AS |

CNS |

| Austenitic stainless steel | |||||||||

|

1 |

12Cr17Mn6Ni5N |

SUS201 |

201 |

S20100 |

STS201 |

1.4372 |

10Cr17Mn6Ni4N20 |

201-2 |

201 |

|

2 |

12Cr18Mn9Ni5N |

SUS202 |

202 |

S20200 |

STS202 |

1.4373 |

- |

- |

202 |

|

3 |

12Cr17Ni7 |

SUS301 |

301 |

S20200 |

STS301 |

1.4319 |

10Cr17Ni7 |

301 |

301 |

|

4 |

06Cr19Ni10 |

SUS304 |

304 |

S30400 |

STS304 |

1.4301 |

07Cr18Ni9 |

304 |

304 |

|

5 |

022Cr19Ni10 |

SUS304L |

304L |

S30403 |

STS304L |

1.4306 |

02Cr18Ni11 |

304L |

304L |

|

6 |

06Cr19Ni10N |

SUS304N1 |

304N |

S30451 |

STS304N1 |

1.4315 |

- |

304N1 |

304N1 |

|

7 |

06Cr19Ni9NbN |

SUS304N2 |

XM21 |

S30452 |

STS304N2 |

- |

- |

304N2 |

304N2 |

|

8 |

022Cr19Ni10N |

SUS304LN |

304LN |

S30453 |

STS304LN |

- |

- |

304LN |

304LN |

|

9 |

10Cr18Ni12 |

SUS305 |

305 |

S30500 |

STS305 |

1.4303 |

- |

305 |

305 |

|

10 |

06Cr23Ni13 |

SUS309S |

309S |

S30908 |

STS309S |

1.4833 |

- |

309S |

309S |

|

11 |

06Cr25Ni20 |

SUS310S |

310S |

S31008 |

STS310S |

1.4845 |

- |

310S |

310S |

|

12 |

06Cr17Ni12Mo2 |

SUS316 |

316 |

S31600 |

STS316 |

1.4401 |

04Cr17Ni12Mo2 |

316 |

316 |

|

13 |

06Cr17Ni12Mo2Ti |

SUS316Ti |

316Ti |

S31635 |

- |

1.4571 |

04Cr17Ni12MoTi20 |

316Ti |

316Ti |

|

14 |

022Cr17Ni12Mo2 |

SUS316L |

316L |

S31603 |

STS316L |

1.4404 |

~02Cr17Ni12Mo2 |

316L |

316L |

|

15 |

06Cr17Ni12Mo2N |

SUS316N |

316N |

S31651 |

STS316N |

- |

- |

316N |

316N |

|

16 |

022Cr17Ni13Mo2N |

SUS316LN |

316LN |

S31653 |

STS316LN |

1.4429 |

- |

316LN |

316LN |

|

17 |

06Cr18Ni12Mo2Cu2 |

SUS316J1 |

- |

- |

STS316J1 |

- |

- |

316J1 |

316J1 |

|

18 |

022Cr18Ni14Mo2Cu2 |

SUS316J1L |

- |

- |

STS316J1L |

- |

- |

- |

316J1L |

|

19 |

06Cr19Ni13Mo3 |

SUS317 |

317 |

S31700 |

STS317 |

- |

- |

317 |

317 |

|

20 |

022Cr19Ni13Mo3 |

SUS317L |

317L |

S31703 |

STS317L |

1.4438 |

- |

317L |

317L |

|

21 |

06Cr18Ni11Ti S |

SUS321 |

321 |

S32100 |

STS321 |

1.4541 |

04Cr18Ni10Ti20 |

321 |

321 |

|

22 |

06Cr18Ni11Nb |

SUS347 |

347 |

S34700 |

STS347 |

1.4550 |

04Cr18Ni10Nb40 |

347 |

347 |

| Duplex stainless steel | |||||||||

|

1 |

- |

SUS329J1 |

329 |

S32900 |

STS329J1 |

1.4477 |

- |

329J1 |

- |

|

2 |

022Cr23Ni5Mo3N |

- |

S32205 |

F60 |

- |

1.4462 |

- |

2205 |

2205 |

|

3 |

022Cr25Ni7Mo4N |

- |

S32750 |

F53 |

- |

1.4410 |

- |

2507 |

2507 |

| Ferritic stainless steel | |||||||||

|

1 |

06Crl3Al |

SUS405 |

405 |

S40500 |

STS405 |

1.4002 |

04Cr13 |

405 |

405 |

|

2 |

022Cr11Ti |

SUH409 |

409 |

S40900 |

STS409 |

1.4512 |

- |

409L |

409L |

|

3 |

022Cr12 |

SUS410L |

- |

- |

STS410L |

- |

- |

410L |

410L |

|

4 |

10Cr17 |

SUS430 |

430 |

S43000 |

STS430 |

1.4016 |

05Cr17 |

430 |

430 |

|

5 |

10Cr17Mo |

SUS434 |

434 |

S43400 |

STS434 |

1.4113 |

- |

434 |

434 |

|

6 |

022Cr18NbTi |

- |

- |

S43940 |

- |

1.4509 |

- |

439 |

439 |

|

7 |

019Cr19Mo2NbTi |

SUS444 |

444 |

S44400 |

STS444 |

1.4521 |

- |

444 |

444 |

| Martensitic stainless steel | |||||||||

|

1 |

12Cr12 |

SUS403 |

403 |

S40300 |

STS403 |

- |

- |

403 |

403 |

|

2 |

12Cr13 |

SUS410 |

410 |

S41000 |

STS410 |

1.4006 |

12Cr13 |

410 |

410 |

|

3 |

20Cr13 |

SUS420J1 |

410 |

S42000 |

STS420J1 |

1.4021 |

20Cr13 |

420 |

420J1 |

|

4 |

30Cr13 |

SUS420J2 |

- |

- |

STS420J2 |

1.4028 |

30 Cr13 |

420J2 |

420J2 |

|

5 |

68Cr17 |

SUS440A |

440A |

S44002 |

STS440A |

- |

- |

440A |

440A |

Packing and delivery

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements. We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

CUSTOMER VISIT

The company always adheres to thequality first, service-oriented principle, to provide our cus.tomers with high-quality steel, and our company has suffi-cient resources, better than the market price to face custom-ers. With the customers' development and common progress,we have built one beneficial cooperation platform.

FACTORY WORKSHOP

The company stocks The quantity is sufficient and the varieties and specifications are complete. The factory has introduced advanced production equipment and testing equipment such as oil mill wire drawing machines, sintering machines, pelletizing machines, and shearing machines.

PARTNER

QUALITY INSPECTION

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

Quality Inspection

APPLICATION AREAS

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples for free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

Type 201 stainless steel is an austenitic chromium-nickel-manganese stainless steel, which is developed to save nickel. Type 201 is a low-cost alternative to traditional Cr-Ni stainless steels such as 301 and 304. The nickel is replaced by added manganese and nitrogen. It cannot be hardened by heat treatment, but can reach high tensile strength by cold working. Type 201 is essentially non-magnetic in the annealed condition and becomes magnetic upon cold working. In many applications, the 201 type may replace the 301 type.

304 stainless steel is a kind of universal stainless steel material, rust resistance than 200 series of stainless steel material is stronger. High temperature resistance is also better, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and good intergranular corrosion resistance. For oxidizing acids, it is concluded in the experiment that 304 stainless steel has strong corrosion resistance in nitric acid with a concentration of less than or equal to 65% of the boiling temperature. It also has good corrosion resistance to alkali solution and most organic and inorganic acids.

316L stainless steel is an austenitic stainless steel metal alloy that contains nickel and molybdenum, making it corrosion resistant. 316L is a 316 low carbon grade. This grade is not affected by sensitization (grain boundary carbide precipitation). It is often used for large-gauge welded parts (approximately over 6mm). 316L stainless steel has higher creep, fracture stress and tensile strength than chromium nickel austenitic stainless steel at high temperature.

301 grade stainless steel is a common austenitic stainless steel with good corrosion resistance and high carbon content, and can be cold worked to various temperatures. Among stainless steels, 301 is the most easily strengthened steel by cold deformation. Cold deformation processing can improve the strength and hardness of steel, and retain sufficient plasticity and toughness. In addition, this steel has good rust resistance under atmospheric conditions, but its corrosion resistance in reducing media is poor, and its corrosion resistance in chemical media such as acid, alkali and salt is poor. Therefore, it is not recommended for corrosive environments.

GET A FREE QUOTE